A water blocking cable is an essential innovation in fiber optic technology, designed to protect delicate fibers from the damaging effects of moisture. In telecommunications, even the smallest amount of water penetration can cause signal attenuation, corrosion of metallic components, and long-term reliability issues. By incorporating water-blocking materials such as gels, tapes, or powder compounds, these cables provide superior resistance against environmental hazards. Companies like Hedot have invested in advanced engineering to ensure their cables deliver uninterrupted performance, even in the most challenging outdoor or underground installations. This makes water blocking cable technology indispensable for industries requiring secure, high-speed communication networks.

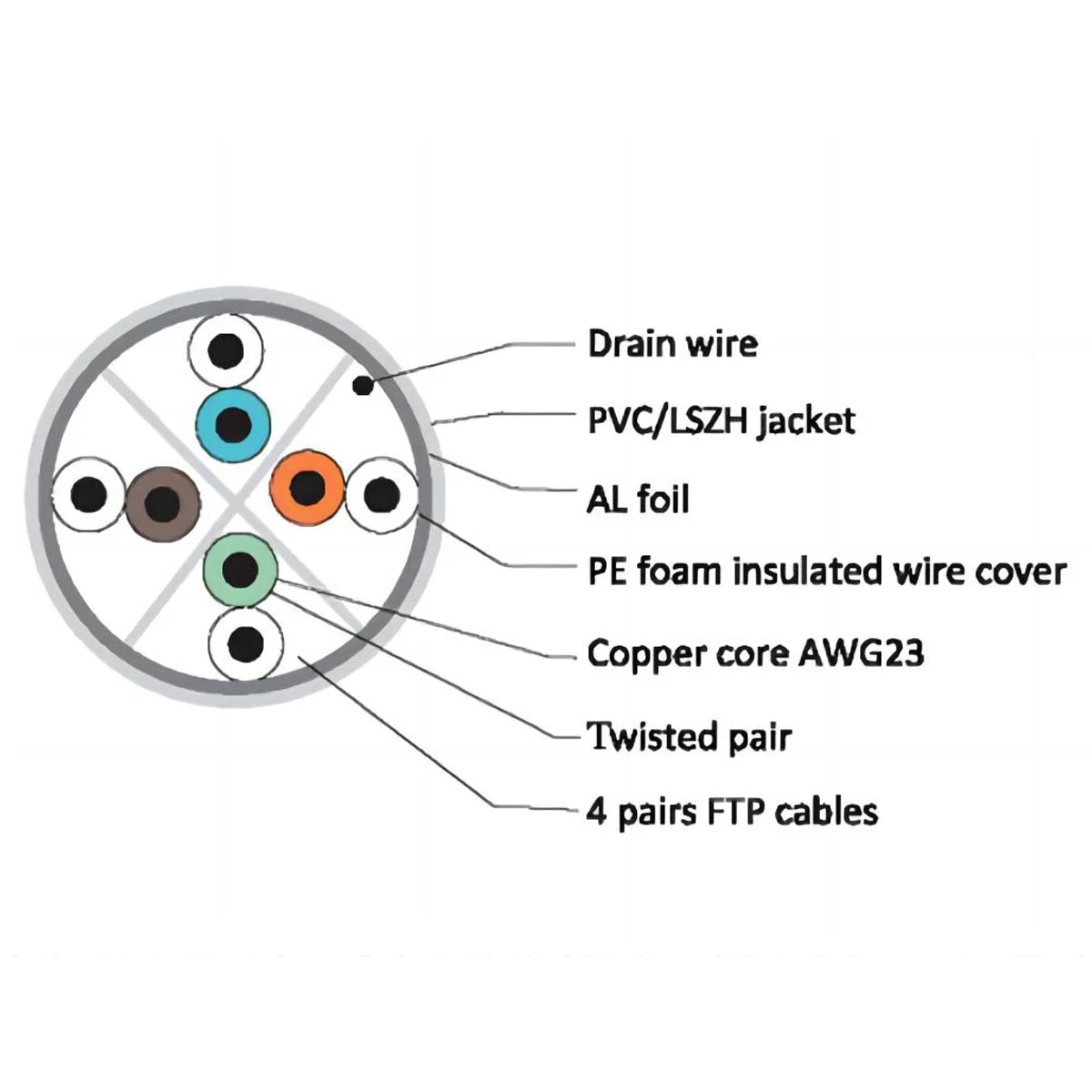

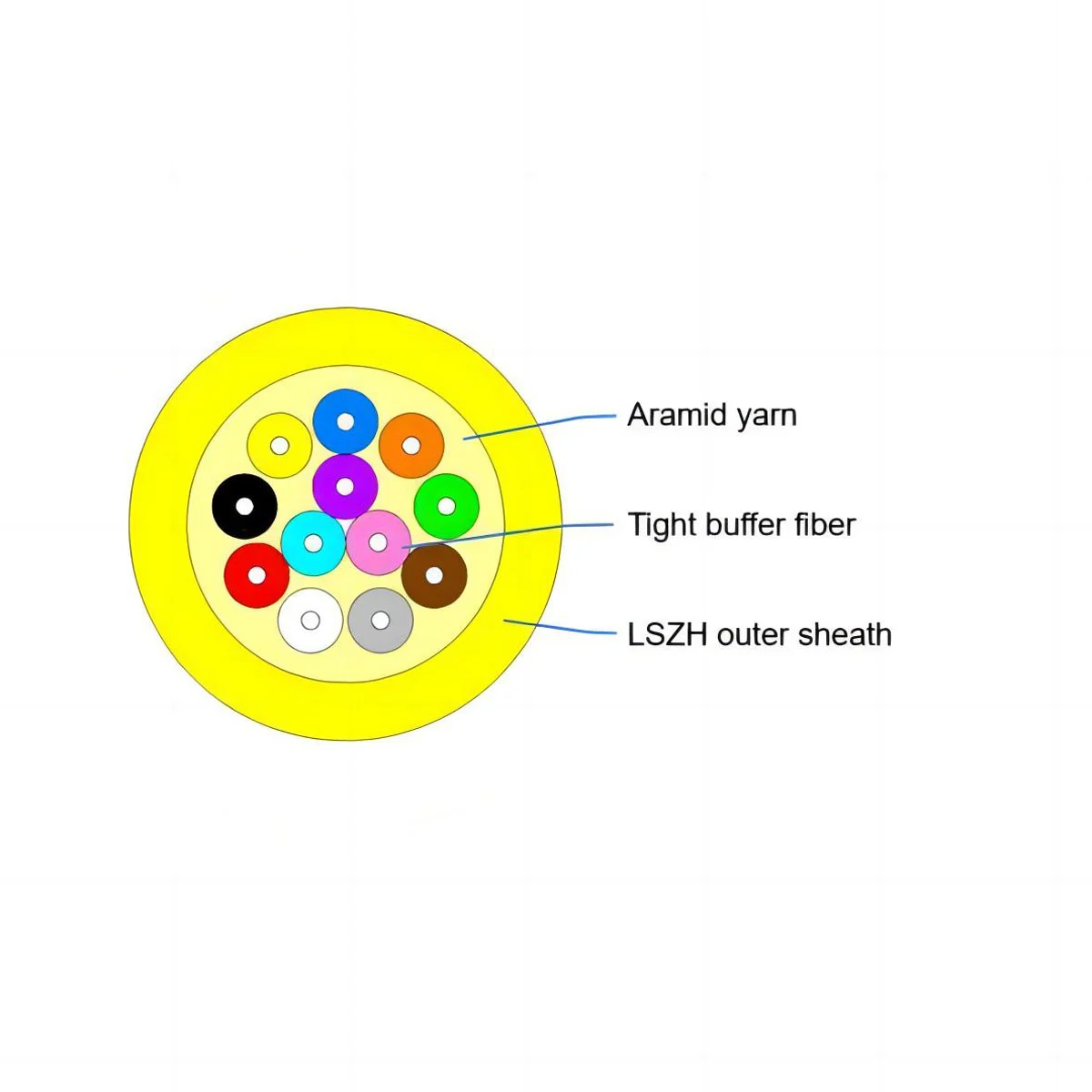

The performance of a water blocking cable relies heavily on its structural design. Typically, these cables feature a protective outer sheath, water-blocking layers, and carefully coated fiber cores. The blocking compounds expand upon contact with moisture, effectively sealing off further ingress and protecting the optical fibers from degradation. Mechanical strength members such as aramid yarn or fiberglass rods are often included to enhance tensile performance, especially for aerial or direct-buried applications. At Hedot, precision in material selection and consistency in manufacturing guarantee that every cable not only resists water but also withstands environmental stress, maintaining both transmission efficiency and long-term durability.

The versatility of a water blocking cable allows it to be used across multiple industries. In telecommunications, it is widely deployed in aerial installations, underground conduits, and submarine systems, where exposure to moisture is unavoidable. The energy sector also benefits, as water blocking cables secure communication lines in remote or offshore facilities. Additionally, infrastructure projects such as railways, highways, and urban communication systems rely on these cables to maintain continuous data transmission in environments prone to flooding or high humidity. With their adaptability, Hedot's cables provide a foundation for resilient connectivity in mission-critical applications worldwide.

One of the growing priorities in fiber optic manufacturing is ensuring sustainability while delivering high performance. A water blocking cable achieves this by reducing the need for frequent repairs or replacements, thereby minimizing material waste and resource use. Modern dry-blocking technologies also eliminate the need for petroleum-based gels, aligning with eco-friendly manufacturing standards. Hedot integrates these sustainable practices into production, combining robust protection with environmental responsibility. As industries expand their networks into more challenging conditions, the balance between reliable performance and ecological awareness makes water blocking cable technology a preferred choice for forward-thinking organizations.