A self support cable is a specialized type of fiber optical cable that integrates its own load-bearing elements, allowing it to be installed in overhead applications without the need for additional support structures. It is primarily used in outdoor overhead lines for telecommunications, power transmission, and broadcasting, especially in scenarios where it is inconvenient or impossible to install messenger wires or brackets, such as across streets, fields, or between utility poles.

Unlike traditional cables that require external steel strands or suspension wires, the self support cable is structurally designed to withstand tension, wind, and its own weight. This provides several advantages including simplified installation, high mechanical strength, and reliable operation.

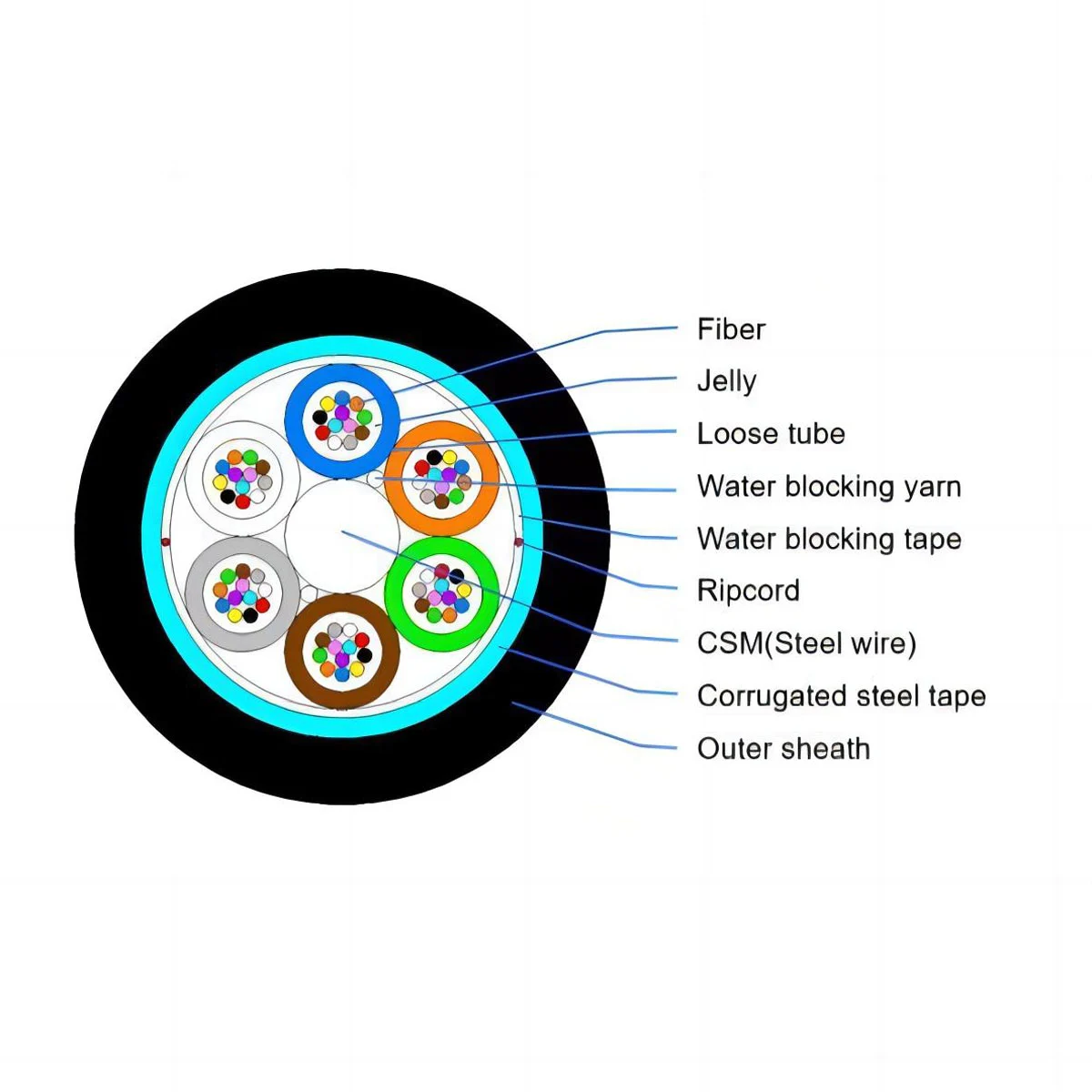

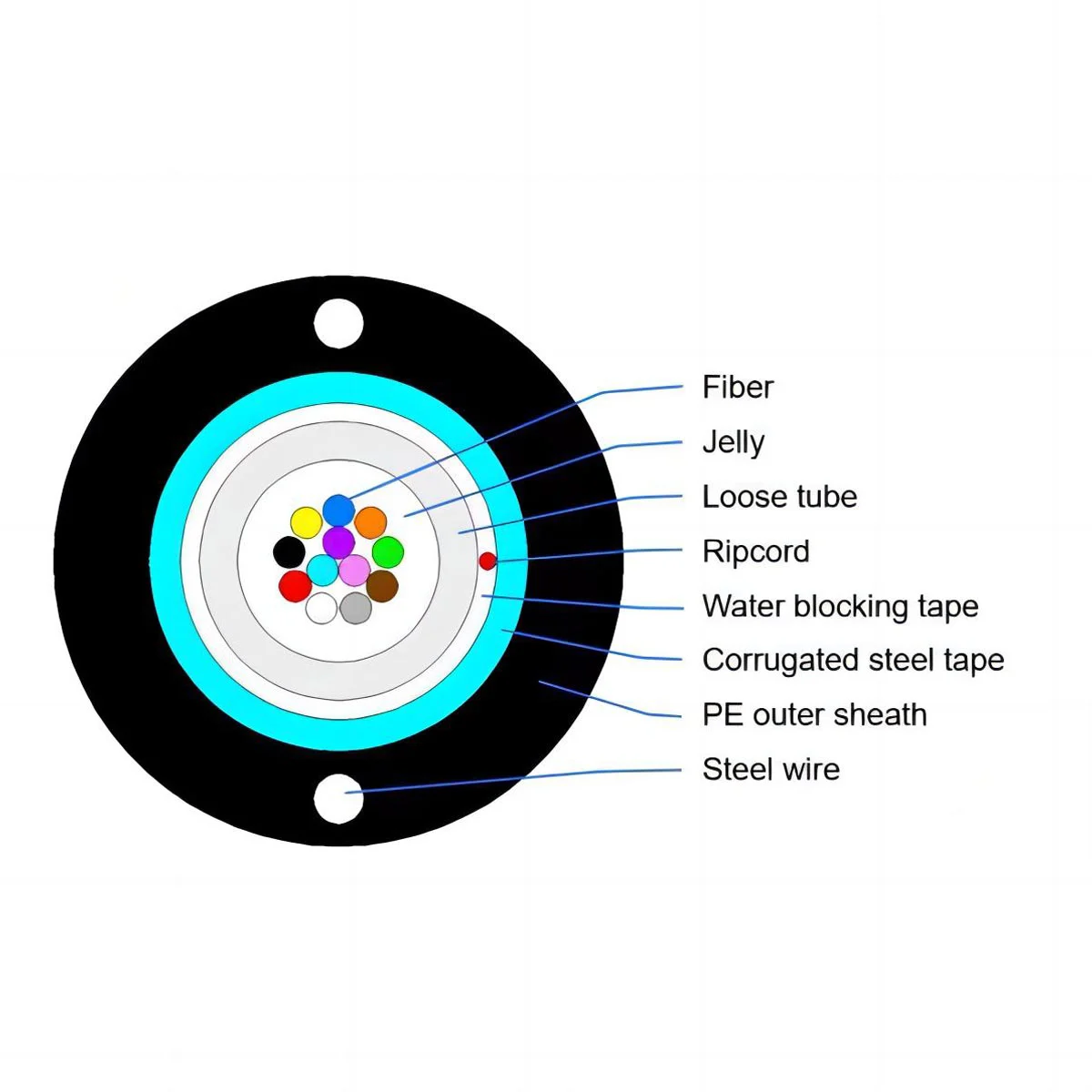

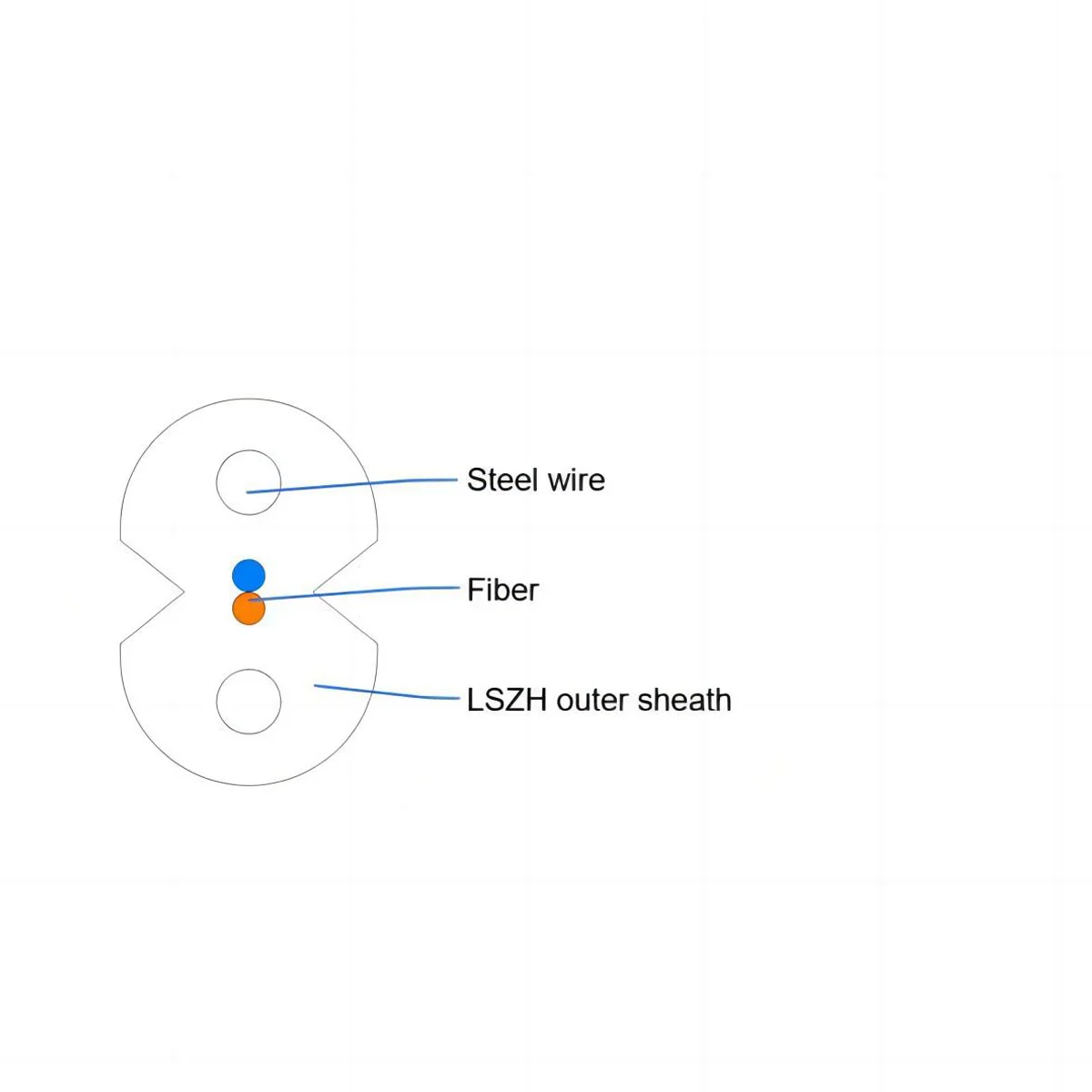

Typically, a self support cable consists of the following components:

Conductor: The part responsible for transmitting power or signals, usually made of copper or aluminum.

Insulation and Sheath Layers: Made from polyethylene (PE) or cross-linked polyethylene (XLPE), offering excellent electrical insulation and weather resistance.

Reinforcement (Load-bearing Element): Such as steel core, steel strand, or high-strength aramid fiber, embedded within the cable to provide tensile strength and structural support.

These components are scientifically engineered to ensure that the outdoor fiber optic cable can withstand its own weight and external loads (e.g., wind pressure, ice, and snow) during overhead installation, without the need for additional traction systems.

Urban and Rural Communication Infrastructure

Self support optical cables are widely used in FTTH (Fiber to the Home) and rural digital infrastructure projects. They are ideal for overhead installations along streets, roads, or on rural utility poles, effectively reducing installation complexity and cost.

Broadcast Network Upgrades

In the modernization of broadcasting and TV networks, self support cables enable fast deployment without disrupting existing facilities, improving signal transmission stability.

Local Power Distribution Lines

In urban grid expansion or temporary power supply projects, short-distance overhead power lines can utilize self support power cables to reduce the number of poles and improve installation efficiency.

No Need for Auxiliary Steel Strands – Easy Installation

Since the self support cable includes built-in load-bearing functionality, it eliminates the need for separate suspension wires and complex fastening processes, greatly enhancing construction speed and flexibility—particularly beneficial in tight spaces or temporary setups.

High Tensile Strength – Suitable for Harsh Environments

The reinforced structure ensures that the cable remains stable under severe conditions such as high wind loads, long spans, and extreme temperature differences. It resists sagging, breakage, and damage, offering a service life of over 20 years.

Low Maintenance – Reliable Operation

With its compact design, corrosion resistance, and aging resistance, the self support cable requires minimal maintenance over time. It is especially suitable for deployment in terrains that are complex or hard to access.