The inner sheath in cable construction plays a fundamental role in ensuring long-term performance and reliability. Acting as a protective barrier between the insulated conductors and the outer sheath, it provides mechanical strength, chemical resistance, and additional insulation. Without this layer, cables would be more vulnerable to external stresses such as abrasion, moisture ingress, and electrical interference. For manufacturers like Hedot, careful engineering of the inner sheath is critical to achieve consistent transmission efficiency while safeguarding the integrity of the cable under varying environmental conditions.

The material used for the inner sheath in cable design significantly impacts its durability and application range. Common materials include polyvinyl chloride (PVC), polyethylene (PE), and low-smoke zero halogen (LSZH) compounds, each offering unique benefits. PVC sheaths are flexible and cost-effective, making them suitable for standard indoor applications. PE sheaths provide enhanced resistance to moisture and chemicals, which is ideal for industrial or outdoor environments. LSZH materials, often used in sensitive installations, minimize toxic emissions during fire incidents. Hedot utilizes advanced material science to optimize these properties, ensuring cables deliver superior protection and performance across multiple sectors.

The choice of inner sheath material depends on the operational requirements of the cable. Different environments demand varying balances of flexibility, resistance, and safety.

Property | PVC Inner Sheath | PE Inner Sheath | LSZH Inner Sheath |

Flexibility | High, easy to handle | Moderate, less flexible | Good, balanced |

Moisture Resistance | Moderate | Excellent | Good |

Fire Safety | Standard | Limited | Excellent, low smoke emission |

Cost | Cost-effective | Slightly higher | Higher due to safety standards |

Ideal Use | Indoor, general wiring | Outdoor, industrial | Public spaces, sensitive areas |

This comparison highlights how the inner sheath in cable selection influences overall cable performance. Hedot integrates tailored sheath materials to address the specific needs of communication networks, balancing mechanical durability, safety, and cost-effectiveness.

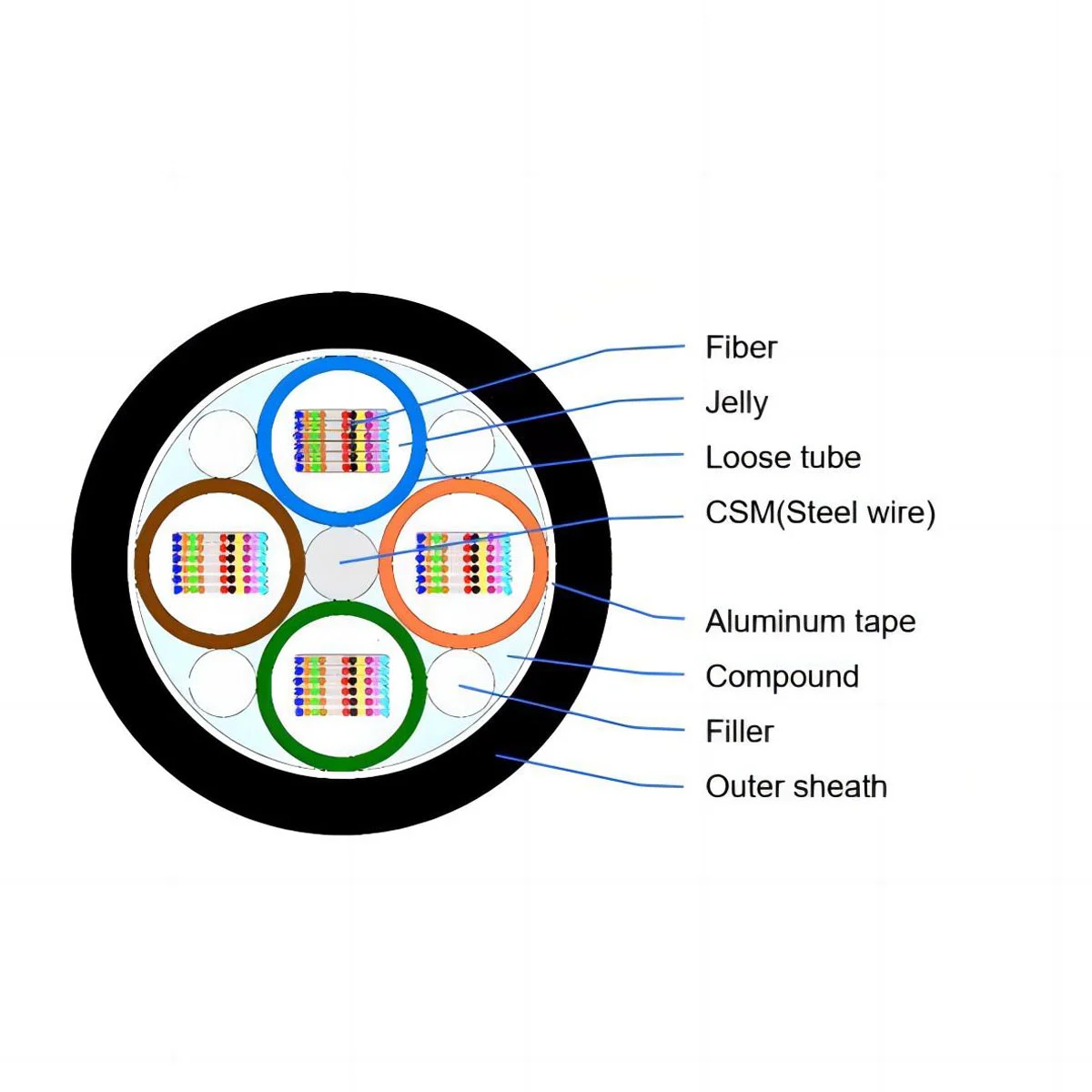

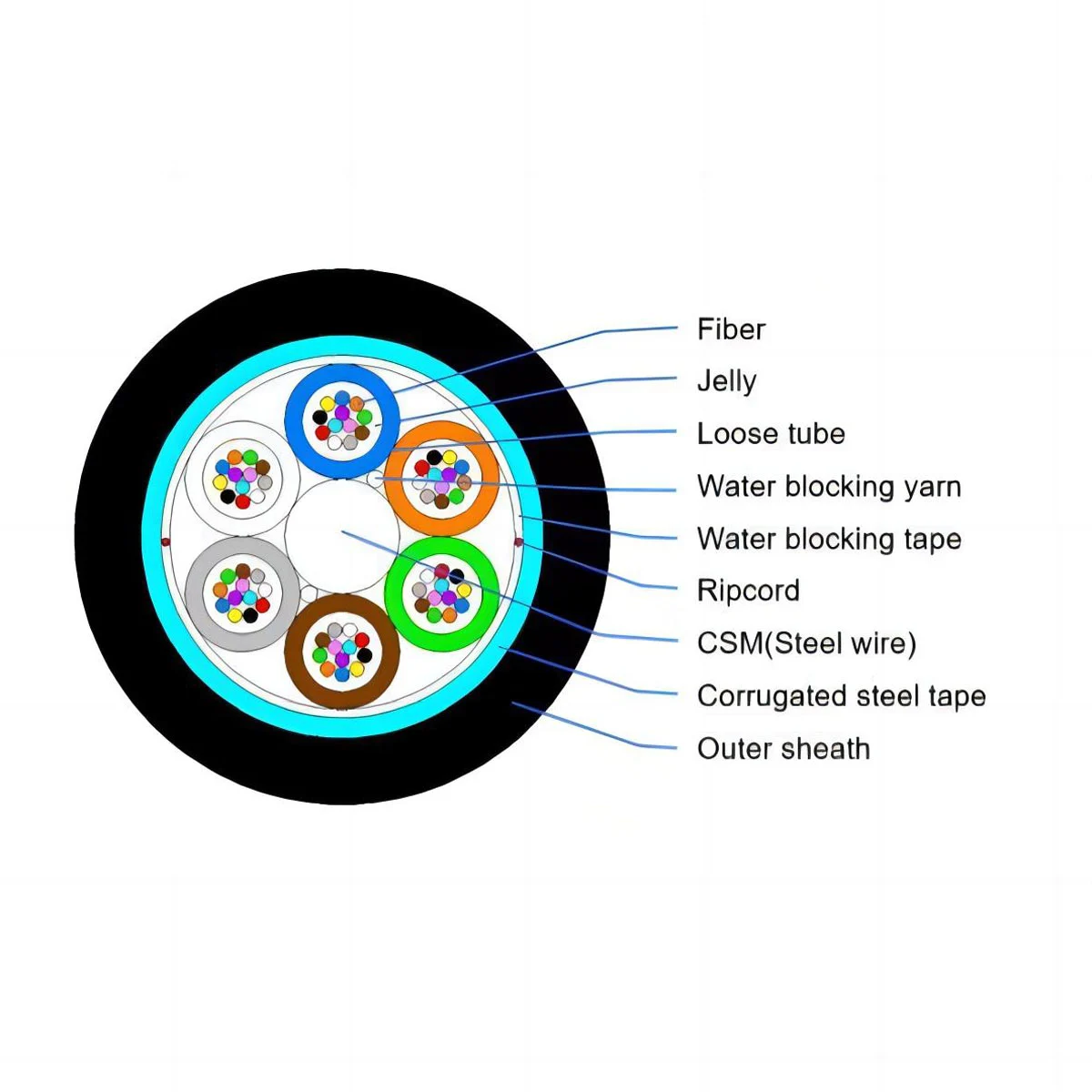

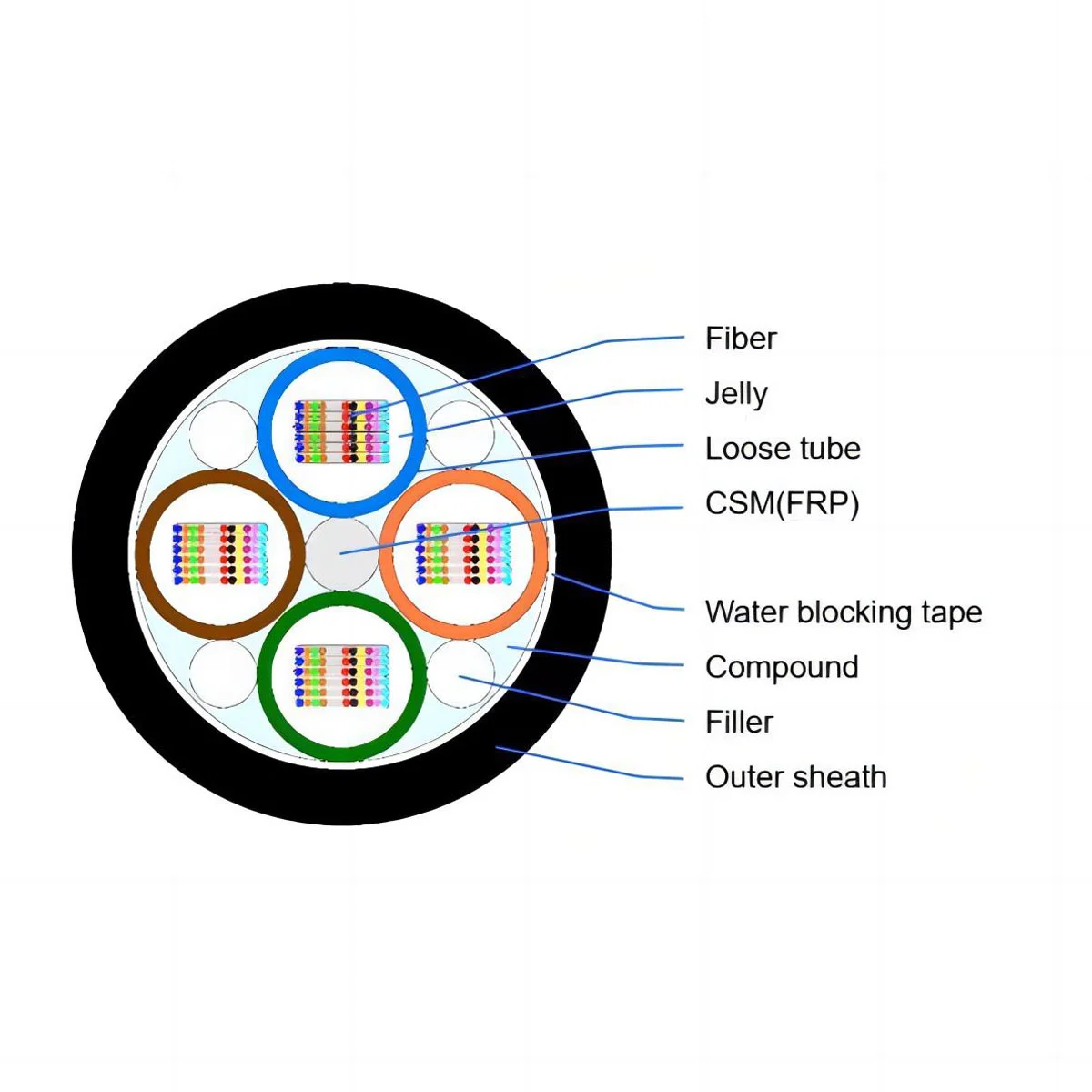

The inner sheath in cable is crucial in both power transmission and communication systems. In fiber optic cables, the sheath protects delicate fibers from crushing forces and environmental hazards. In power cables, it ensures the insulation system remains intact under electrical and thermal stress. Applications range from aerial installations to underground ducts, where resistance to water, heat, and chemicals is essential. Hedot designs inner sheath structures that support stable connectivity in telecommunications, data centers, energy networks, and infrastructure projects, ensuring reliability in demanding environments.

As technology advances, the inner sheath in cable has evolved from a simple protective layer to a highly engineered component. Modern sheath designs incorporate flame-retardant additives, anti-rodent treatments, and enhanced thermal stability. These innovations extend the service life of cables while reducing maintenance costs. Manufacturers like Hedot focus on precision extrusion and stringent testing to ensure every sheath layer performs consistently under stress. With continuous development, the inner sheath is now a critical factor in determining the resilience and safety of modern cable systems.