In modern power and communication engineering, the cable plays a vital role as the carrier of energy and information. Its structural design directly impacts operational safety and efficiency. The inner sheath in cable is an intermediate protective layer between the internal structure and the outer sheath. It is usually made from materials such as polyvinyl chloride (PVC), polyethylene (PE), or low-smoke, halogen-free compounds. Its primary functions are protection, insulation, and structural stabilization, making it an indispensable part of the cable system.

Protecting Conductors and Insulation Layers

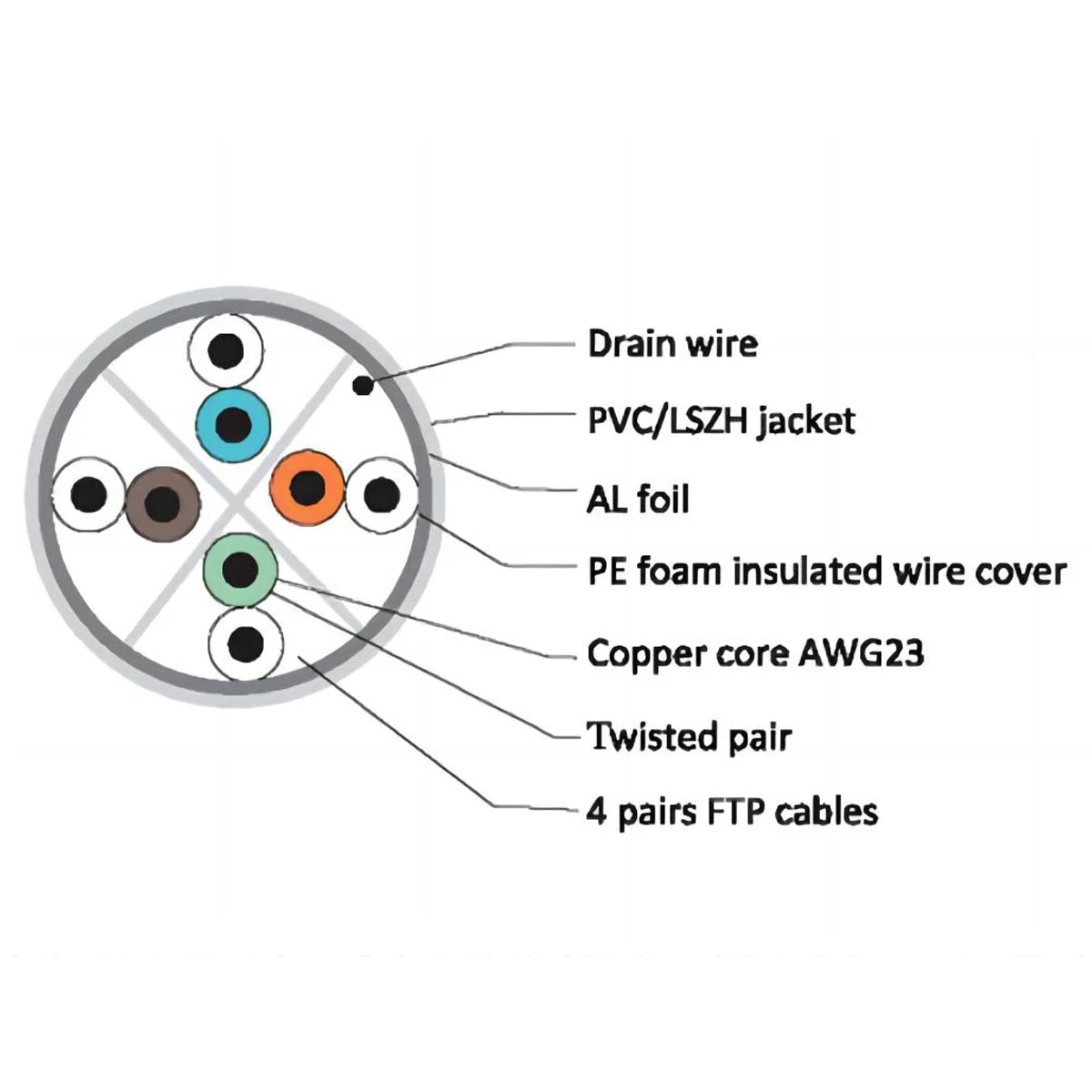

Inside a communications cable are multiple conductors and insulated cores. If directly exposed to mechanical forces or chemical environments, these components can suffer damage—such as insulation breakdown, conductor deformation, or even short circuits. The inner sheath in cable acts as the first "soft armor", effectively preventing damage from friction, compression, or vibration during installation and operation.

Enhancing Structural Stability of the Cable

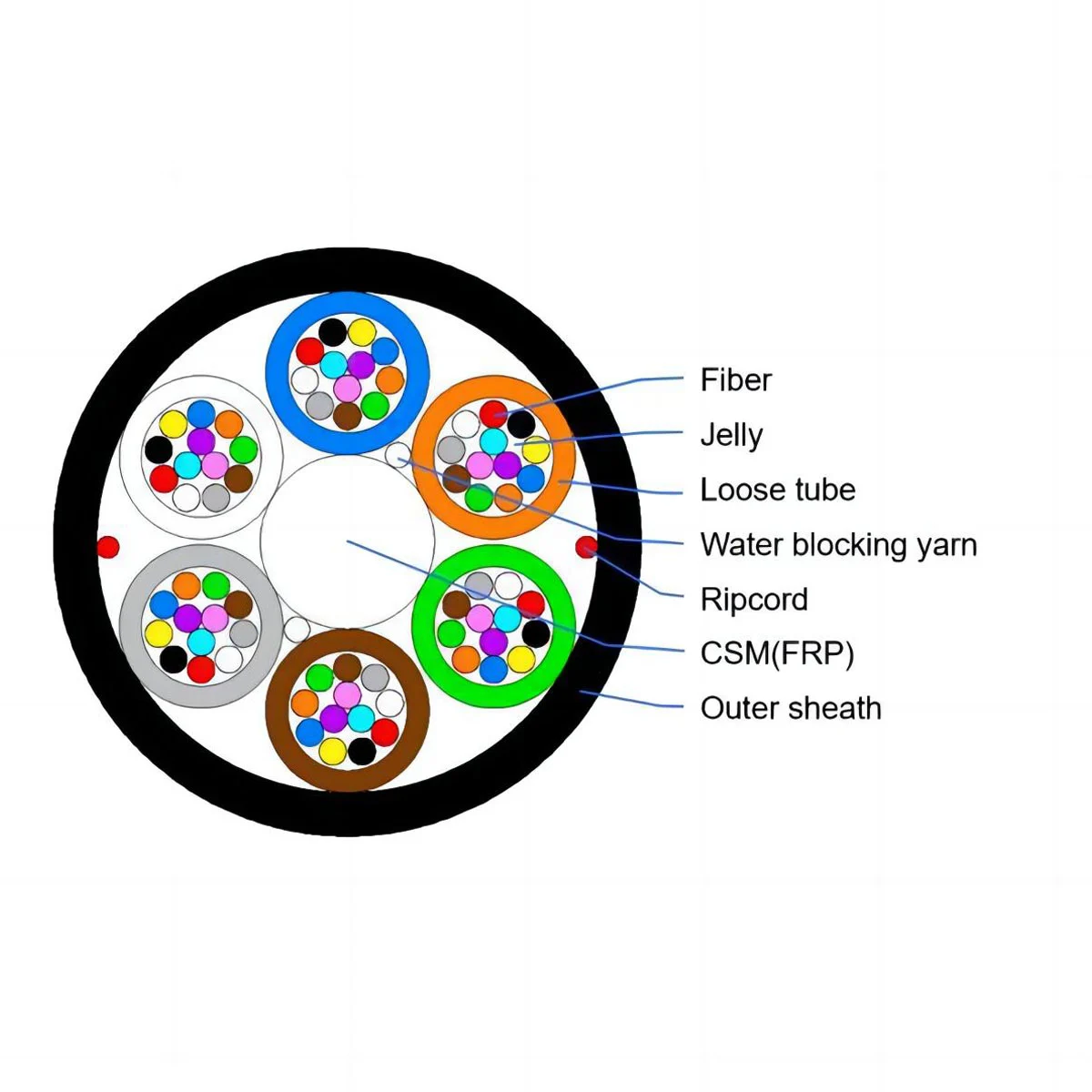

The inner sheath of cable tightly binds multi-core cables together, helping to maintain roundness and proper alignment. It minimizes displacement or deformation of internal cores due to thermal expansion, contraction, or external tension, thus increasing the overall mechanical strength.

Improving Moisture and Corrosion Resistance

Cables are often used in underground, marine, or high-humidity environments. The inner sheath of cable offers excellent resistance to water and corrosion, effectively blocking moisture and corrosive chemicals from reaching internal components and thereby extending the cable's service life.

Application in Control Cables

Control cables must transmit signals stably and require strong anti-interference capability. The inner sheath of cable, when used in conjunction with shielding layers, forms a reliable electromagnetic barrier, significantly reducing external interference and ensuring accurate signal transmission.

Application in High-Voltage or Special-Purpose Cables

In high-voltage or mining cables, the material used for the inner sheath in cable must offer superior thermal stability and mechanical strength to withstand intense electric fields and complex environmental pressures. Its excellent heat resistance ensures long-term stable performance under heavy load.

Role in Low-Smoke, Halogen-Free Environmental Cables

In environmentally friendly cables, the inner sheath in cable is made from halogen-free compounds. Even in the event of a fire, it does not release toxic smoke, ensuring safer evacuation for personnel and protecting sensitive equipment.

With the advancement of smart manufacturing and new energy technologies, global cable solutions are evolving toward lighter, smarter, and more extreme-environment-resistant designs. In the future, materials used in the inner sheath in cable may incorporate nanocomposite technologies, self-healing features, and temperature-sensing functions, allowing the sheath not only to protect but also to "sense" environmental changes and actively adjust its protective strategy.

Although not the most prominent part of a cable, the inner sheath in cable is like the inner lining of armor—silently ensuring the safety and stability of the entire system. With its combined functions of structural reinforcement, protection, and environmental adaptability, it is a cornerstone of cable durability and reliability. In modern cable engineering, a scientifically designed and well-selected inner sheath in cable is the key to dependable cable performance.